post from:blog.isa.org/

Introduction介绍

Pumps, compressors, and distillation columns are commonly used in the process industry. Measuring the pressure or head of the system requires a pressure gauge or sensor. Because of faulty installation or variations, remote pressure sensors or local pressure gauges can produce unexpected results. They occasionally perplex the process engineer, such as when downstream pressure exceeds upstream pressure in the flow direction. Here, we will look at all the issues concerning pressure sensors and value discrepancies. This blog will provide knowledge of pressure measurement as well as recommendations.

泵、压缩机和蒸馏塔通常用于过程工业。测量系统的压力或扬程需要压力表或传感器。由于错误的安装或变化,远程压力传感器或本地压力表可能会产生意想不到的结果。它们有时会使过程工程师感到困惑,例如当下游压力在流动方向上超过上游压力时。在这里,我们将研究有关压力传感器和值差异的所有问题。该博客将提供有关压力测量的知识和建议。

When a fluid travels or flows through a pipeline, pressure is classified into two categories: Static and dynamic. An installed pressure sensor typically detects or experiences the static pressure only. If the pressure gauge is tapped in the streamline, it also measures the dynamic pressure. The sum of static and dynamic pressure is known as total pressure; total pressure is always greater than the static pressure, except when dynamic pressure is zero.

当流体在管道中流动或流动时,压力分为两类:静态压力和动态压力。安装的压力传感器通常仅检测或承受静压。如果压力表在流线中被抽头,它也测量动态压力。静压和动压之和称为总压;总压力总是大于静态压力,除非动态压力为零。

Here are some examples of pressure transmitter installation issues that cause erratic pressure readings, such as when the pressure downstream in the flow direction is greater than the pressure upstream, the pressure in the heat exchanger outlet is greater than the pressure in the inlet, and the pressure at the bottom of the vessel is lower than the top and pressure at the bottom of the distillation column is lower than the top. Such reading discrepancy leads us to believe that the transmitter is malfunctioning, although it is possible that the pressure measurement tape was fitted incorrectly.

以下是导致压力读数不稳定的压力变送器安装问题的一些示例,例如当流动方向下游压力大于上游压力时,换热器出口压力大于入口压力,以及容器底部的压力低于顶部,蒸馏塔底部的压力低于顶部。这种读数差异使我们相信变送器出现故障,尽管压力测量带可能安装不正确。

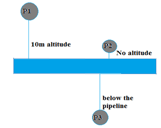

1. Altitude of pressure transmitter: When pressure transmitters are located far below the tapping elevation, the transmitter tubing becomes liquid-filled, and this liquid exerts some excess pressure owing to the liquid head. Extra pressure must be read by the pressure sensor if the transmitter is not compensated or calibrated as a wet leg. This is solely a liquid service or condensing vapor application, such as steam, propylene, or a heavier hydrocarbon vapor.

1、压力变送器的高度:当压力变送器的位置远低于取水高度时,变送器管内充满液体,由于液头的作用,这种液体会产生一定的过压。如果变送器未作为湿腿进行补偿或校准,则压力传感器必须读取额外压力。这仅适用于液体服务或冷凝蒸汽应用,例如蒸汽、丙烯或较重的碳氢化合物蒸汽。

Another source of worry is that the transmitter is elevated above the tapping in the process, which contains condensing vapor that can condense at ambient temperatures. Condensate will fill the tubing, and the transmitter will read a different pressure than the actual. In such circumstances, the tubing should be self-draining or compensated for extra leg.

另一个令人担忧的来源是变送器在过程中升高到高于取压口,其中含有可在环境温度下凝结的冷凝蒸汽。冷凝水将充满管道,变送器将读取与实际压力不同的压力。在这种情况下,管道应该是自排空的或补偿额外的腿。

Refer to Figure 1 to see the three different pressure transmitters elevated at different height. Due to altitude, all three would produce different readings in the same pipeline. P1 sensor reads a low pressure because it is filled with liquid, whereas P3 shows a higher pressure due to the liquid head. P2 is perfectly installed and well elevated.

请参阅图 1,查看在不同高度升高的三种不同压力变送器。由于海拔高度的原因,这三个都会在同一管道中产生不同的读数。 P1 传感器读取的压力较低,因为它充满了液体,而 P3 由于液体压头而显示出较高的压力。 P2 已完美安装且提升良好。

Figure 1

In distillation tower pressure gauge or sensor installed in downcomer by mistake, this will also read as an extra head of liquid. These need to be checked during the design phase. In distillation towers, where vapor can condense at ambient temperature, pressure sensor tubing must be self-draining or positioned at the same elevation.

在蒸馏塔压力表或传感器错误安装在降液管中,这也将被视为额外的液体压头。这些需要在设计阶段进行检查。在蒸馏塔中,蒸汽会在环境温度下凝结,压力传感器管道必须是自排空的或位于相同的高度。

2. Pressure momentum: Unknowingly, pressure taping is placed in front of the nozzle in many operations, where the high-velocity fluid comes and strikes the tape. This pressure sensor measures static pressure as well as the additional fluid momentum induced by dynamic pressure. Because this pressure meter measures both dynamic and static pressure, it always reads greater than any other adjacent transmitter. Feed nozzle or reboiler outlet nozzle fluid might hit the pressure sensor and cause abnormal readings in compressor knock-out drums, separator vessels, and distillation columns. In a distillation column, a pressure gauge installed at the bottom (above the maximum expected liquid level) of the column can also read higher pressure than normal due to momentum.

2. 压力动量:在许多操作中,不知不觉中,压力胶带被放置在喷嘴前面,高速流体从此处进入并撞击胶带。该压力传感器测量静态压力以及由动态压力引起的额外流体动量。由于此压力计同时测量动态和静态压力,因此它的读数始终大于任何其他相邻的变送器。进料喷嘴或再沸器出口喷嘴流体可能会撞击压力传感器并导致压缩机分离罐、分离器容器和蒸馏塔中的读数异常。在蒸馏塔中,由于动量,安装在塔底(高于最大预期液位)的压力表也可以读取高于正常值的压力。

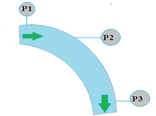

3. At the elbow of the pipeline: Pressure sensors or gauges should not be installed at the elbow of the pipeline in any service. Liquid flows due to pressure difference, and it will contain static as well dynamic pressure. When it is installed at the elbow, it senses the dynamic pressure also and shows a higher reading.

3、管道弯头处:在任何使用中,管道弯头处不应安装压力传感器或压力表。液体由于压力差而流动,它会包含静压和动压。当它安装在弯头处时,它也会感应动态压力并显示更高的读数。

Cooling water is flowing via a pipeline, and three pressure sensors are mounted at various points. The first pressure sensor is implanted upstream of the elbow, the second on the elbow, and the third downstream of the elbow. P2 will have a higher reading than P1 and P3. Figure 2 is a simple representation of this. The P2 sensor sees the momentum or velocity head of the flowing fluid and shows the reading of total pressure (static pressure and dynamic pressure).

冷却水通过管道流动,三个压力传感器安装在不同的位置。第一个压力传感器植入在肘部的上游,第二个在肘部,第三个在肘部的下游。 P2 的读数将高于 P1 和 P3。图 2 是对此的简单表示。 P2 传感器检测流动流体的动量或速度头,并显示总压力(静态压力和动态压力)的读数。

Figure 2

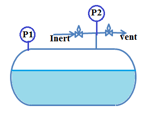

4. At the pipeline instead of the tank: In the process industry, vessels or surge tanks are used to store hydrocarbons, either as a suction drum of a pump or as a feed drum to a plant. These tanks were constantly pressurized with inerts such as nitrogen or fuel gas to impose pressure to assist the pump's net positive suction pressure (NPSP) and to prevent any intrusion from the environment.

4. 在管道而不是储罐:在过程工业中,容器或稳压罐用于储存碳氢化合物,作为泵的吸入鼓或作为工厂的进料鼓。这些储罐不断地用氮气或燃气等惰性气体加压,以施加压力以辅助泵的净正吸入压力 (NPSP) 并防止来自环境的任何侵入。

A pressure transmitter (as seen in Figure 3) is fitted to maintain pressure in the tank or vessel, and pressure is maintained in the tank or vessel using a PIC controller or PCV. Pressure sensors are installed in the pipeline (P2) rather than the tank (P1) in some plants. These pressure sensors would read deviation due to flow of gas. There is a continual flow of nitrogen or hydrocarbon vapor through the nitrogen pipeline or vent line, and the vessel or tank’s top would not properly manage the pressure. It would occasionally remain lower than planned, while other times it would remain higher than set points. So, pressure sensors always should be installed on the vessel or tank directly such as P1 instead of P2 to control the static pressure of the vessel accurately.

安装压力变送器(如图 3 所示)以维持储罐或容器中的压力,并使用 PIC 控制器或 PCV 维持储罐或容器中的压力。在某些工厂中,压力传感器安装在管道 (P2) 而不是罐 (P1) 中。由于气体流动,这些压力传感器会读取偏差。氮气或碳氢化合物蒸汽持续流过氮气管道或排气管,容器或罐顶无法正确控制压力。它偶尔会低于计划值,而其他时候会高于设定值。因此,压力传感器总是应该直接安装在容器或储罐上,如P1而不是P2,以准确控制容器的静压。

Figure 3

5. Before a fully developed flow: In fluid mechanics, we address the boundary layer separation phenomenon. The boundary layer divides when fluid enters the pipelines, and the velocity profile of the fluid across the pipeline alters until it fully develops. This velocity profile is also affected by whether the fluid is flowing laminarly or turbulently. Due to the turbulent nature of most fluid flows, the pressure sensor should be fitted after the flow has been fully developed. The velocity profile in fully developed flow is parabolic in laminar and somewhat flatter in turbulent, and the velocity near the wall is virtually nil. To obtain the accurate measurement, a pressure sensor should be inserted after the fully developed flow or after the entrance length. The pressure near the wall is merely static pressure, and the sensor only reads static pressure rather than total pressure.

5. 在完全发展的流动之前:在流体力学中,我们解决了边界层分离现象。当流体进入管道时,边界层会分开,并且流体穿过管道的速度分布会发生变化,直到它完全发展。该速度分布还受流体是层流流动还是湍流流动的影响。由于大多数流体流动的湍流特性,应在流动完全发展后安装压力传感器。完全发展的流动中的速度剖面在层流中呈抛物线,在湍流中略微平坦,壁附近的速度几乎为零。为了获得准确的测量值,应在完全发展的流量之后或入口长度之后插入压力传感器。靠近墙壁的压力仅仅是静压,传感器只读取静压而不是总压。

6. Plugging/chocking/coking of tubing: Many processes in the process industries use congealing, slurry, heavy tar, or coke material. Pressure measurement is difficult in such a process. This tar or coke can deposit in the pressure sensor tubing and jam or choke the pressure transmitter tube, causing it to report an erroneous pressure and mislead the operator about the process. To minimize direct contact between the viscous or thick slurry and the pressure sensor, several industries adopted a remote-seal pressure sensor. However, in a remote seal, a diaphragm monitors pressure, which is then converted by the transmitter. This coke or slurry can deposit on the diaphragm, necessitating the use of an external fluid to flush the deposited material. Examples of such services are slurry circulation in FCCU and heavy oil in DCU and quench oil circulation in steam cracker units.

6. 管道的堵塞/堵塞/焦化:过程工业中的许多过程都使用凝结、泥浆、重焦油或焦炭材料。在这样的过程中压力测量是困难的。这种焦油或焦炭会沉积在压力传感器管道中,堵塞或堵塞压力变送器管道,导致其报告错误的压力,并在过程中误导操作员。为了尽量减少粘稠或稠浆与压力传感器之间的直接接触,一些行业采用了远程密封压力传感器。然而,在远程密封中,隔膜监测压力,然后由变送器转换。这种焦炭或泥浆会沉积在隔膜上,需要使用外部流体来冲洗沉积的材料。此类服务的示例包括 FCCU 中的泥浆循环和 DCU 中的重油以及蒸汽裂解装置中的淬火油循环。

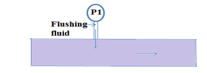

7. Flushing/purging with external fluid: Congealing services or viscous materials capable of solidifying at ambient temperature are required for some flushing, as previously indicated. External fluid flushing is also required to remove the accumulated material. External flushing fluid should be compatible with pipeline fluid or internal fluid. Steam, nitrogen, or any other appropriate liquid can be used as external fluids. External high-pressure fluid is fed into the pressure sensor tube or diaphragm when a pressure sensor is installed in this type of congealing or viscous operation.

7. 用外部流体冲洗/清洗:如前所述,某些冲洗需要凝结服务或能够在环境温度下凝固的粘性材料。还需要进行外部流体冲洗以去除积聚的物质。外部冲洗液应与管道流体或内部流体兼容。蒸汽、氮气或任何其他合适的液体都可以用作外部流体。当在这种类型的凝结或粘性操作中安装压力传感器时,外部高压流体被送入压力传感器管或隔膜。

Figure 4: Flushing fluid injection

These high-pressure external fluids generate tremendous velocity to flush the deposited materials. The pressure sensor detects this high velocity of the external fluid and reads an incorrect value because the low-pressure zone near the pressure sensor's diaphragm or tubing is caused by the rapid and high velocities of the external fluid (see Figure 4). Because of inadequate flow metering, the flow of external fluid or purging gas is very high in some plants. This high flow can result in a high-pressure reading due to pressure accumulation or buildup.

这些高压外部流体产生巨大的速度来冲洗沉积的材料。压力传感器检测到这种高速的外部流体并读取不正确的值,因为压力传感器隔膜或管道附近的低压区是由外部流体的快速和高速引起的(见图 4)。由于流量计量不足,某些工厂的外部流体或吹扫气体流量非常高。由于压力累积或累积,这种高流量会导致高压读数。

8. After expander of pipeline: The process industry pipeline is laid throughout the plant and contains numerous elbows, tees, and expanders. According to the Bernoulli principle, as the area of the pipeline expands owing to expansion, the velocity slows, and the kinetic energy is turned into pressure energy. As a result, the pressure sensor downstream (P2) detects a higher pressure than the pressure sensor (P1) upstream (see Figure 5). This is also true vice versa.

8. 管道扩口后:流程工业管道布设在整个工厂,包含许多弯头、三通和扩口。根据伯努利原理,随着管道面积的膨胀,速度变慢,动能转化为压力能。因此,下游压力传感器 (P2) 检测到的压力高于上游压力传感器 (P1)(见图 5)。反之亦然。

Figure 5: Pressure sensor after expander

9. Dual phase pressure measurement: When process stream contains the condensing vapor or dual phase in the pipelines, pressure values can be surprising due to condensation. When vapor is flowing through the pipelines, at one point the pressure sensor reads a certain pressure value. However, due to heat loss or any cooler (heat exchanger), that vapor would partially condense, slowing the velocity of the dual phase slightly due to condensation and increment in the pressure. This signifies that the pressure downstream of the cooler, or heat loss owing to ambient, is larger than the pressure upstream. It might be surprising, but this happens due to the Bernoulli’s principle or “effect,” as described in more detail in reference 7.

9. 双相压力测量:当过程流在管道中含有冷凝蒸汽或双相时,由于冷凝,压力值可能会令人吃惊。当蒸汽流过管道时,压力传感器会在某一点读取某个压力值。然而,由于热损失或任何冷却器(热交换器),该蒸汽会部分冷凝,由于冷凝和压力增加而稍微减慢双相的速度。这表示冷却器下游的压力或由于环境造成的热损失大于上游的压力。这可能令人惊讶,但这是由于伯努利原理或“效应”而发生的,如参考文献 7 中更详细的描述。

Conclusion结论

A pressure sensor or pressure measurement is the most basic equipment for reading pressure, although the reading might be perplexing or misleading due to installation alteration. These are some recommendations to avoid such design errors and erratic pressure readings:

压力传感器或压力测量是读取压力的最基本设备,尽管由于安装变更,读数可能会令人困惑或误导。这些是避免此类设计错误和压力读数不稳定的一些建议:

- Always use siphon tubes or liquid filed tubing in steam or high temperature services to avoid direct contact of steam with pressure gauges or transmitters.

- Always calibrate pressure sensors based on situation wet and dry leg.

- Pressure sensor should be away from the momentum of fluid and elbow of the pipeline.

- Always check plugging, chocking, or coking of the tubing of pressure transmitters and flush the transmitter tubing with compatible fluid in intervals.

- Always install pressure sensor 10D after the mixing point to get fully developed flow.

- A pressure sensor must be put directly on the vessel or tank instead of the pipeline if continuous static pressure is to be maintained in the tank or vessel.

- Always utilize remote seal pressure sensors in corrosive or caustic environments.

- During the continual flushing of pressure sensors, the flushing flow should be monitored.

- In distillation columns, pressure sensors should be installed in vapor phase and checked during the design phase to avoid downcomer installation.

- 始终在蒸汽或高温服务中使用虹吸管或液体管,以避免蒸汽与压力表或变送器直接接触。

- 始终根据湿腿和干腿的情况校准压力传感器。

- 压力传感器应远离流体动量和管道弯头。

- 始终检查压力变送器管道的堵塞、堵塞或焦化情况,并定期用兼容流体冲洗变送器管道。

- 始终在混合点后安装压力传感器 10D,以获得充分发展的流量。

- 如果要在储罐或容器中保持连续静压,则必须将压力传感器直接放在容器或储罐上而不是管道上。

- 在腐蚀性或腐蚀性环境中始终使用远程密封压力传感器。

- 在连续冲洗压力传感器的过程中,应监测冲洗流量。

- 在蒸馏塔中,压力传感器应安装在气相中,并在设计阶段进行检查,以避免安装降液管。

Note: This blog is not related to any specific company and is based on author experience and learning for knowledge-sharing only.

注:本博客与任何具体公司无关,仅根据作者经验和学习进行知识分享。

References

- Wikimedia Foundation. (2022, October 4). Pressure measurement. Wikipedia. Retrieved January 5, 2023, from https://en.wikipedia.org/wiki/Pressure_measurement

- Lieberman, N. P., & Lieberman, E. T. (2014). Working Guide to Process Equipment. McGraw-Hill Education.

- Sharma, A. (2022, April 1). The Flaws of Flow Meters. Retrieved January 5, 2023, from https://blog.isa.org/the-flaws-of-flow-meters

- Kister, H. Z. (1990). Distillation Operation. McGraw-Hill Education.

- Sharma, A. (2022, July). Caustic tower design guidelines and recommendations. Hydrocarbon Processing. Retrieved January 5, 2023, from https://www.hydrocarbonprocessing.com/magazine/2022/july-2022/process-optimization/caustic-tower-design-guidelines-and-recommendations

- Baukal, C. E. (2013). The John Zink Hamworthy Combustion Handbook. CRC Press.

- Lieberman, N. P. (2017). Process Engineering: Facts, Fiction and Fables. Wiley.

Abhishek Sharma is a process engineer at an ethylene plant. He has more than four years of experience in the steam cracker unit. He completed his B.Tech in chemical engineering from the National Institute of Technology Raipur, India with honors and completed process equipment design and process plant design courses from IIT Roorkee and IIT KGP, respectively. He is an active professional member of the American Institute of Chemical Engineers and an associate member of IChemE. He is currently involved in the smooth operation and troubleshooting of the plant.

Abhishek Sharma 是一家乙烯厂的工艺工程师。他在蒸汽裂解装置方面拥有超过四年的经验。他以优异的成绩获得了印度赖布尔国家理工学院的化学工程学士学位,并分别完成了 IIT Roorkee 和 IIT KGP 的工艺设备设计和工艺工厂设计课程。他是美国化学工程师学会的活跃专业会员和 IChemE 的准会员。他目前参与工厂的平稳运行和故障排除。

More Stories

PETROBRAS巴西石油公司

KNPC科威特国家石油公司

北海油田