Vibration near a control valve installation can originate from many sources. Here’s how to pinpoint problems and provide solutions.Julian Mann

控制阀安装附近的振动可能来自许多来源。这是查明问题并提供解决方案的方法。朱利安·曼(Julian Mann)

作者:Julian Mann

翻译:Gordon

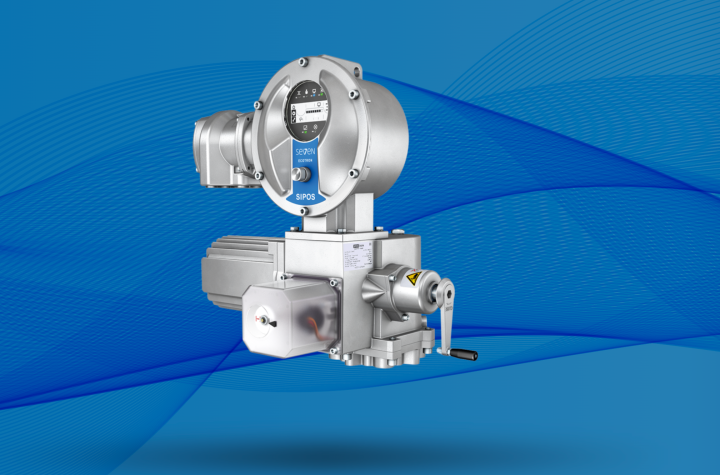

图3.技术人员在带噪声调整和排气扩散器的截止阀上安装了一个加速度计,以将振动转换成噪声。所有图形均由艾默生自动化解决方案提供

Excessive vibration can cause damage to a control valve, measurement equipment and the piping system. Plants often try to fix problems by measuring vibration, moving equipment, stiffening the valve structure, rewelding broken pipes, changing the piping system and other remedies — only to find problems still exist.

过度的振动会损坏控制阀,测量设备和管道系统。工厂经常尝试通过测量振动,移动设备,加固阀门结构,重新焊接破损的管道,更换管道系统和其他补救措施来解决问题,直到发现问题仍然存在。

This is because it is often difficult to find the source of the vibration, which can originate not only with the control valve, but also with upstream and downstream piping and equipment.

这是因为通常很难找到振动源,该振动源不仅可能来自控制阀,还可能来自上游和下游管道和设备。

This article will discuss modern techniques to help monitor, predict and solve problems caused by vibration in the vicinity of control valves.

本文将讨论现代技术,以帮助监视,预测和解决由控制阀附近的振动引起的问题。

图1.控制阀振动导致该阀杆断裂。所有图形均由艾默生自动化解决方案提供

Vibration sources

振动源

Vibration experienced in control valve installations can be caused by pump cavitation, flow pulsation, flow-induced excitations, vortex shedding, rapid valve closure, vapor pocket collapse, pump startup and shutdown, slug flow, water hammer and many other hard-to-diagnose conditions.

控制阀装置中的振动可能是由泵的气蚀,流动脉动,流动引起的激励,涡流脱落,快速的阀关闭,蒸气囊塌陷,泵的启动和关闭,团状流,水锤和许多其他难以诊断的引起的条件。

For example, the valve plug can vibrate and cause damage to the cage, or it can cause a fatigue failure such as the stem breaking where it is connected to the plug. The results of the cage damage can be higher friction and thus poor valve assembly performance. If the valve stem breaks, the valve ceases to function.

例如,阀芯会振动并导致阀笼损坏,或者会导致疲劳故障,例如阀杆与阀芯连接处的阀杆断裂。阀笼损坏的结果可能是较高的摩擦力,从而导致阀组件性能不佳。如果阀杆断裂,则阀将停止工作。

In some cases, valves and piping can shake so badly that workers are afraid to go near the system for fear the piping will burst. In other cases, the valve noise generated is excessive.

在某些情况下,阀门和管道会剧烈震动,以至于工人担心管道破裂会害怕靠近系统。在其他情况下,产生的阀门噪音过大。

Two common types of vibration are associated with control valve installations. Acoustically induced vibration (AIV) generates excessive levels of high-frequency acoustic energy that can cause fatigue failure of welded downstream connectors. This is often seen in liquid natural gas emergency blowdown systems, but is also found in other process piping systems. The noise levels generated by the valve and other piping elements are high enough to cause damaging vibration to the piping system.

两种常见的振动类型与控制阀安装有关。声诱发振动(AIV)会产生过多的高频声能,从而导致下游焊接连接器疲劳失效。这在液态天然气紧急排污系统中经常可见,但在其他过程管道系统中也可见。阀门和其他管道元件产生的噪音水平足够高,会对管道系统造成有害的振动。

Flow-induced vibration (FIV) generates high levels of kinetic energy that can cause piping vibration, loosen piping supports and cause fatigue failure at piping branches (see Figure 2).

流动引起的振动(FIV)产生高水平的动能,这些动能会引起管道振动,松动管道支撑并导致管道分支疲劳失效(见图2)。

Excessive vibration can damage a control valve’s accessories, such as mounting brackets, actuator tubing, transmitters and actuators. Actuator tubing can suffer fatigue failures at or near the nut/ferrule location, causing pressure to be lost in the tubing. Without pressure in the tubing, the actuator cannot be controlled and/or pressure signals between control components are lost. In either case, the valve ceases to function as designed.过度的振动会损坏控制阀的附件,例如安装支架,执行器气源管路,变送器和执行器。执行器气源管路在螺母/卡套位置或附近可能会遭受疲劳破坏,从而导致管路中的压力损失。如果在气源管道中没有压力,则无法控制执行器和/或失去控制组件之间的压力信号。在这两种情况下,阀门均无法按设计运行。

Vibration can also cause fatigue failures in nearby measurement components, such as pressure or temperature instruments installed in the downstream or upstream piping. This vibration can damage an instrument or degrade the instrument’s connection to the piping. Damage to an instrument can result in loss of the measurement signal, and failure of the connection to the piping can cause leaks.

振动还会导致附近测量组件的疲劳失效,例如安装在下游或上游管道中的压力或温度仪表。这种振动会损坏仪器或降低仪器与管道的连接。仪器损坏可能会导致测量信号丢失,与管道的连接失败会导致泄漏。

Vibration can cause fatigue failure in piping, especially at welds and branch locations. At the very least, vibration is annoying because of the noise generated. At worst, vibration can destroy piping, cause leaks and prevent the valve from controlling a process. In either case, one of the most difficult problems is determining what causes the vibration.

振动会导致管道疲劳失效,尤其是在焊缝和分支位置。至少,由于产生的噪音,振动令人讨厌。在最坏的情况下,振动会破坏管道,导致泄漏并阻止阀门控制过程。无论哪种情况,最困难的问题之一就是确定引起振动的原因。

图2.流动引起的振动和声音引起的振动会破坏焊接,松开管道支架,引起疲劳问题并关闭过程。

Measuring vibration

测量振动

Vibration is measured with accelerometers placed at various points on the valve and actuator assembly, and upstream and downstream of the valve. While vibration can be measured with handheld devices, the preferred solution is to use wireless, battery-powered accelerometers (see Figure 3).

振动是通过放置在阀门和执行器组件上各个点以及阀门上游和下游的加速度计进行测量的。虽然可以使用手持设备测量振动,但首选的解决方案是使用电池供电的无线加速度计(见图3)。

Older vibration sensors commonly used to find problems in motors, pumps and other rotating equipment that may not be suitable for diagnosing valve vibration. These vibration sensors often operate in the low-frequency range of 1,000 hertz (Hz) or less, while control valve AIV can reach levels of 3 to 5 kilohertz and even higher.

较旧的振动传感器通常用于发现电动机,泵和其他旋转设备中可能不适合诊断阀振动的问题。这些振动传感器通常在1,000赫兹(Hz)或更低的低频范围内工作,而控制阀AIV可以达到3至5千赫兹甚至更高的水平。

Vibration sensors are installed for two basic reasons: First, to measure the vibration in and around the valve and assess its severity in various locations; second, to assess changes and reductions in vibration after corrective measures are taken.

振动传感器的安装有两个基本原因:首先,测量阀门内部和周围的振动并评估阀门在各个位置的严重程度;其次,在采取纠正措施后评估振动的变化和减少。

In most cases, sensors are mounted on the valve bonnet, stem connector, actuator, and/or inlet and outlet piping. If specific damage or high vibration occurs in one area, a sensor is typically mounted near the area of interest. In the case of a hot system, such as a steam line, sensors have a mounting to isolate the sensing element from the high temperature.

在大多数情况下,传感器安装在阀盖,阀杆连接器,执行器和/或入口和出口管道上。如果在一个区域中发生特定的损坏或强烈振动,则通常会在目标区域附近安装传感器。在热系统(例如蒸汽管线)的情况下,传感器具有将感应元件与高温隔离的支架。

Sensor placement may also be dictated by acoustic measurements that identify high noise sources. To determine if the noise source is upstream of the valve — with noise then propagating through the system — sensors can be mounted upstream and downstream of the valves, and on the valve stem.

传感器的放置也可能由识别高噪声源的声学测量决定。为了确定噪声源是否在阀的上游(有噪声然后通过系统传播),可以在阀的上游和下游以及阀杆上安装传感器。

If the highest vibration levels are found next to a valve, the source or cause of the noise is most likely the valve trim components.

如果在阀旁发现最高的振动水平,则噪声的来源或原因很可能是阀内件的组件。

If the highest vibration is downstream, the problem may be closely coupled systems, where valves are too close to elbows and other equipment, causing flow-induced turbulence. Piping systems are sometimes designed with an elbow or tee near the valve inlet. Unfortunately, this provides a turbulent flow into the valve, which can result in more vibration than typical in the valve and additional turbulence in the piping downstream of the valve, causing excess vibration.

如果最大的振动是在下游,则问题可能出在紧密耦合的系统上,其中阀门离弯头和其他设备太近,从而导致流动引起的湍流。有时将管路系统设计为在阀入口附近带有弯头或三通。不幸的是,这提供了进入阀的湍流,这可能导致比阀中的典型振动更大的振动,并且导致阀下游的管道中的附加湍流,从而导致过度的振动。

Similarly, the piping may be designed where an elbow or tee is placed directly downstream of the valve. The flow from the valve outlet can interact with the piping element, causing high turbulence and vibration. Both situations can be solved by moving piping elements farther upstream or downstream of the valve. In general, it is best to keep elbows at least 20 diameters before and 6 diameters after a valve.

类似地,可以在将弯头或三通直接放置在阀门下游的地方设计管道。来自阀出口的流动会与管道元件相互作用,从而引起高湍流和振动。两种情况都可以通过将管道元件移到阀门的上游或下游来解决。通常,最好使肘部在阀前至少20个直径,在阀后至少6个直径。

A modern wireless vibration sensor provides complete vibration data including overall levels, energy bands, high resolution spectra and waveforms. Some sensors can measure vibration up to 20,000 Hz and transmit the measured vibration data over a wireless network to the plant’s control and monitoring system or PC-based software for analysis. If desired, the PC can upload data to the cloud where it can be accessed from any location with internet access.

现代的无线振动传感器可提供完整的振动数据,包括总体水平,能带,高分辨率频谱和波形。一些传感器可以测量高达20,000 Hz的振动,并将测量的振动数据通过无线网络传输到工厂的控制和监视系统或基于PC的软件进行分析。如果需要,PC可以将数据上传到云,在这里可以从任何可以访问Internet的位置进行访问。

One advantage of such a system is that it will acquire data at a set interval, such as every minute or every few hours. This allows vibration to be measured often over a period of several days, weeks or months. These vibration measurements can then be trended to reveal patterns leading to failure, allowing corrective action to be taken beforehand.

这种系统的一个优点是它将按设定的时间间隔(例如每分钟或每隔几个小时)获取数据。这样可以在几天,几周或几个月的时间内测量振动。然后可以将这些振动测量趋势化,以揭示导致故障的模式,从而可以事先采取纠正措施。

Manual systems are handheld and require an operator present to make the measurement, so these measurements are typically made much less frequently, often only when vibration is high.

手动系统是手持式的,并且需要在场的操作员进行测量,因此通常仅在振动较高时才进行,这种测量方式不经常采用。

Other useful data for analyzing vibration issues includes:

用于分析振动问题的其他有用数据包括:

- Acoustic readings from sound

声音中的声音读数 - Measurement sensors

测量传感器 - Process variable measurements of flow, pressure and temperature

流量,压力和温度的过程变量测量 - General data related to adjacent equipment and its operation

与相邻设备及其操作有关的一般数据 - Indications that blowoff or relief valves have opened or closed

排气阀或溢流阀已打开或关闭的指示 - Control system actions such as opening and closing valves, starting and stopping pumps, or other actions to control a process

控制系统动作,例如打开和关闭阀门,启动和停止泵,或其他控制过程的动作

By analyzing vibration data and looking for correlations between vibration and changing process conditions, engineers can identify the root cause of the vibration.

通过分析振动数据并查找振动与变化的工艺条件之间的相关性,工程师可以确定振动的根本原因。

图4.与过程变化(例如打开和关闭阀门)相比,随时间变化的振动和声级图可以识别出过度振动的根源。

Analyzing the data

分析数据

Data from the vibration sensors can be sent to a process plant’s control and monitoring system, but analysis can be difficult because it often requires a high level of expertise, along with specialized training and tools, to extract usable information from the data.

振动传感器的数据可以发送到加工厂的控制和监视系统,但是分析可能很困难,因为它通常需要高水平的专业知识以及专门的培训和工具,才能从数据中提取可用信息。

Computational fluid dynamics (CFD) is a software tool used to predict fluid behavior. CFD cannot predict the acoustic field in the piping system at AIV frequencies. While these software programs may offer the option to perform predictive maintenance, the results typically compare poorly to the actual acoustic field as measured by sensors.

计算流体动力学(CFD)是用于预测流体行为的软件工具。 CFD无法预测AIV频率下管道系统中的声场。尽管这些软件程序可能提供执行预测性维护的选项,但结果通常与传感器所测量的实际声场相比差。

A better solution than CFD or analysis by operators viewing control and monitoring system screens is specialty analysis software, which cuts through the complexity of vibration analysis to provide a simple, reliable indication of equipment health via a single trend. One such software filters out traditional vibration signals to focus on impacting, a better indicator of overall asset health. Using the software, vibration data is analyzed for frequencies, amplitudes of displacement, velocity and acceleration, and characteristics of the vibration and changes in the vibration over time.

专用分析软件比CFD或操作员查看控制和监视系统屏幕进行分析的解决方案更好,它可以减少振动分析的复杂性,从而通过单一趋势提供简单,可靠的设备运行状况指示。一种这样的软件可以过滤掉传统的振动信号,以聚焦于冲击,这是整体资产健康状况的更好指标。使用该软件,可以分析振动数据的频率,位移幅度,速度和加速度,振动特性以及振动随时间的变化。

For example, the software looks for peaks in the frequency spectrum. Peaks are indications of resonance in the response of a system that is excited, or the excitation being generated at a tone.

例如,该软件在频谱中查找峰值。峰值是在被激励系统的响应中谐振的指示,或者是在音调下产生激励。

An example of the excitation being generated at tones, a compressor will likely create a signal at a set of frequencies, so response at those frequencies indicates response to the input. If the excitation is turbulence, and a peak in the measured vibration is present, that would be an indication of a resonance. If the vibration is broad, it is an indication of an area of strong turbulence in the flow. Mitigation actions are different depending on the type of excitation and response, so it is important to identify problems precisely.

在音调上产生激励的一个例子,压缩器很可能会在一组频率上产生信号,因此在这些频率下的响应表示对输入的响应。如果激发是湍流,并且测得的振动出现峰值,则表明存在共振。如果振动很大,则表明流中存在强烈的湍流区域。缓解措施因激励和响应的类型而异,因此准确识别问题非常重要。

If vibration levels increase over time, this indicates a change in the system. Plant personnel can use this information to explore changes in process settings to reduce vibration to an acceptable level. They may also be able to identify high vibration levels for a set of process conditions and limit the time the process runs with settings causing these conditions.

如果振动水平随时间增加,则表明系统发生了变化。工厂人员可以使用此信息来探索过程设置的变化,以将振动降低到可接受的水平。他们还能够针对一组过程条件识别高振动水平,并使用导致这些条件的设置限制过程运行的时间。

An increase in vibration can also indicate an imminent or present structural failure. The software combined with knowledge of the system can reveal these types of failures and distinguish them from other failure modes (see Figure 4).

振动的增加也可能表示即将发生或目前出现的结构故障。结合系统知识的软件可以揭示这些类型的故障,并将它们与其他故障模式区分开(参见图4)。

Plots of vibration intensities and sound level over time for the sensors in Figure 1 showed sudden amplitude increases associated with process changes.

图1中传感器随时间变化的振动强度和声级图显示,振幅突然增加与过程变化相关。

In another case, when investigating the reason for damage to actuator tubing, analysis showed a direct correlation between a calculated indicator and process pressure. When the indicator reached a maximum value, the tubing failed.

在另一种情况下,当调查致动器油管损坏的原因时,分析表明计算出的指示器与过程压力之间存在直接关系。当指示器达到最大值时,管道发生故障。

图5.艾默生在此蒸汽排放系统上安装了无线振动传感器,以分析引起裂纹故障的振动原因。

Solving a steam let-down system vibration problem

解决蒸汽排放系统的振动问题

An ethanol plant in Minnesota had been plagued by vibration problems for years in a steam let-down system (see Figure 5) that affected the valve, piping, diffuser and steam header. The let-down system reduced steam pressure from 125 psig to 12 to 14 psig, prior to flow into a steam diffuser.

明尼苏达州的一家乙醇厂多年来一直遭受振动问题的困扰,这是因为蒸汽排放系统(见图5)影响了阀门,管道,扩散器和蒸汽集管。排泄系统在流入蒸汽扩散器之前将蒸汽压力从125 psig降低到12到14 psig。

Specific problems included repeated weld and component failures on or around the steam diffuser that were plaguing the plant and causing unplanned downtime. Repairs to the diffuser cost $70,000, valve repairs cost $28,000 and installing steam separators cost $60,000. And every time the system had to be shut down for repairs, it cost the company $100,000 in lost production.

具体问题包括蒸汽扩散器上或周围的重复焊接和组件故障,这些故障困扰着工厂并导致计划外停机。扩散器的维修费用为$ 70,000,阀门维修的费用为$ 28,000,安装蒸汽分离器的费用为$ 60,000。每次必须关闭该系统进行维修时,都会使公司损失10万美元的生产成本。

The plant changed the diffuser, tried different materials, moved the valve farther away from the diffuser, and called in consultants. Nothing worked. Independent vibration analyses indicated high vibration levels but did not identify causes.

工厂更换了扩散器,尝试了不同的材料,将阀门移离扩散器更远,并请来了顾问。没有效果。独立的振动分析显示较高的振动水平,但没有确定原因。

Although the valve was not a Fisher valve, Emerson sent in engineers to measure vibration and analyze the problem. They installed wireless vibration sensors upstream and downstream of the valve, and on the valve and actuator. Correlating vibration data, operational information and historian data showed that the problem was not being caused by the valve, but was instead directly related to process changes.

尽管该阀不是费希尔阀,艾默生还是派出工程师来测量振动并分析问题。他们在阀门的上游和下游以及阀门和执行器上安装了无线振动传感器。振动数据,操作信息和历史数据的相关性表明,问题并非由阀门引起,而是与过程变化直接相关。

Specifically, the diffuser was oversized, which caused excessive pressure drops. This correlation was found by examining the data from the vibration sensors and operating data from the diffuser.

具体而言,扩散器尺寸过大,导致压力降过大。通过检查来自振动传感器的数据和来自扩散器的运行数据,发现了这种相关性。

Summary

摘要

Excessive vibration can damage valves, actuators and piping. Although sensors can measure vibration, locating the root cause of problems can be difficult. What is needed in many cases is specialty software to analyze the vibration, process data and extensive domain expertise to correlate vibration data with process conditions. If this expertise is not available in-house, external experts can often provide the required assistance.

过度的振动会损坏阀门,执行器和管道。尽管传感器可以测量振动,但是很难找到问题的根本原因。在许多情况下,需要使用专用软件来分析振动,过程数据以及广泛的领域专业知识,以将振动数据与过程条件相关联。如果内部没有这种专门知识,则外部专家通常可以提供所需的帮助。

Julian Mann is a principal engineer at Emerson for its flow controls products. He holds a Bachelor of Science in engineering science from Iowa State University and a Ph.D. in acoustics from Penn State. Prior to working at Emerson, Mann was an associate professor and assistant dean at Iowa State.朱利安·曼(Julian Mann)是艾默生(Emerson)的流量控制产品的首席工程师。他拥有爱荷华州立大学的工程科学理学学士学位和博士学位。来自宾夕法尼亚州立大学的音响专业。在Emerson工作之前,Mann是爱荷华州立大学的副教授兼助理院长。

Shawn Anderson is an engineering specialist at Emerson. He has a Bachelor of Science in mechanical engineering from Milwaukee School of Engineering. Anderson leads a team focused on next-generation diagnostics, prognostics and controls for its flow controls products.

Shawn Anderson是艾默生的工程专家。他拥有密尔沃基工程学院的机械工程学学士学位。 Anderson领导的团队致力于其流量控制产品的下一代诊断,预测和控制。

More Stories

解决乙烯的流量控制挑战(第 1 部分)——增加供应,同时减少排放

克服控制阀内件的选择困难

可靠的控制阀–工艺性能和正常运行时间的基础